The Importance of Preventative Maintenance for Quattroflow Pumps

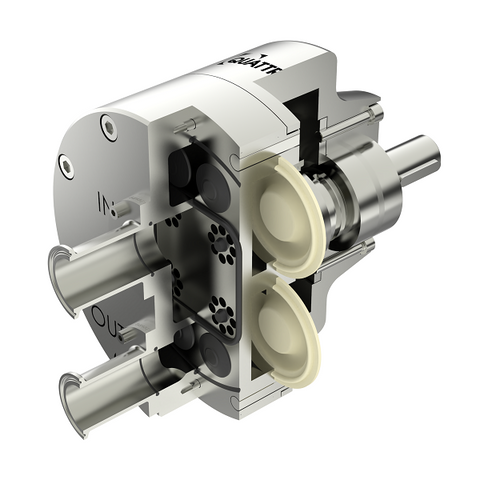

Quattroflow pumps are widely used in the biopharmaceutical and pharmaceutical industries due to their reliability and high-level performance. However, like any other equipment, Quattroflow pumps require periodic maintenance to ensure optimum functionality and long life and prevent costly unplanned downtimes. This blog post will explore the importance of preventative care for Quattroflow pumps and how Liquidyne’s Quattro-Care program can provide seamless uptime and reliability for your biopharma manufacturing operations.The Consequences of Downtime

When Quattroflow pumps are not properly maintained, it can result in reduced performance, decreased efficiency, and costly unplanned downtimes. In a production process where every minute counts, production stoppages can cause expensive delays, product loss, and missed customer deadlines. Preventative maintenance enables you to identify and fix any issues before they become more significant problems that can cause a system failure.

Improved Performance and Longevity

Periodic maintenance can improve the overall performance of your Quattroflow pumps. By replacing worn or faulty elastomer kits and shaft bearing kits and checking outputs, you help to prevent leaks, reduce vibration, and extend the life of your pumps. A well-maintained pump runs at peak efficiency, ensuring that you use less energy during production runs, resulting in significant cost savings.

Preventive Maintenance Saves Money

Preventive maintenance may initially seem like an added cost, but the cost-benefit is extraordinary. Investing in Liquidyne’s Quattro-Care preventative maintenance plan is a cost-effective way to maintain your Quattroflow pumps, identify problems early, and reduce costly unscheduled downtime. Regular maintenance can save you money in repairs, replacement costs, and lost production time in the long run.

Compliance with Industry Standards

Biopharma manufacturing is governed by strict regulations and guidelines that have to be adhered to ensure safety and product quality. These regulations cover all equipment used in the production process, including Quattroflow pumps. Regular maintenance will keep your equipment in compliance with industry standards and ensure the safety and integrity of the production process.

Partner with Liquidyne for Peace of Mind

As Quattroflow pumps’ experts with over 30 years of experience in the biopharmaceutical and pharmaceutical industries, you can trust us to provide tailored preventive maintenance plans that will help keep your production process running smoothly and efficiently. Our Quattro-Care program is designed to meet the needs of process engineers, buyers, scientists, and MRO managers by providing custom solutions and timely maintenance services.

In conclusion, Quattroflow pumps are an essential component in biopharma manufacturing. Preventive maintenance is vital to ensure that production is robust, efficient, and reliable to prevent costly unplanned downtimes. By partnering with Liquidyne, you have peace of mind knowing that your Quattroflow pumps are in good hands, ensuring seamless uptime and reliability for your biopharma manufacturing operations. Contact us today, and never miss a beat in your biopharma manufacturing process.

Explore Liquidyne

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device