Top 10 Reasons to Adopt Aflex Hoses in Your Applications

As a process engineer, MRO manager, buyer, or scientist, you are always looking for top-quality products for your applications. One key component that can significantly affect your processes is the type of hose you use. Various kinds of hoses are available in the market, but none beats Aflex hoses in terms of quality, durability, and efficiency. With over 40 years of experience in manufacturing PTFE hoses, Aflex is a trusted brand in the industry. This blog will comprehensively delve into the top ten reasons you should adopt Aflex hoses in your applications.Excellent Chemical Resistance

Aflex hoses are made using PTFE, which is recognized as a chemical-resistant material. This means that the hoses have excellent resistance to most chemicals, including strong acids and bases. This attribute makes Aflex hoses ideal for use in various chemical processing applications.

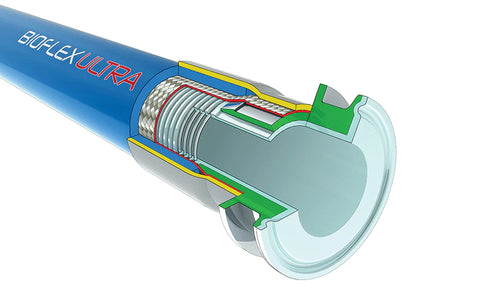

Superior Flexibility

Aflex hoses are highly flexible and can withstand extreme temperatures without cracking or becoming brittle. This makes them ideal for applications requiring flexibility, such as moving machinery parts, tight connections, and other applications involving frequent motion and vibration.

Longer Life Span

Aflex hoses have a longer life span than other hoses in the market. Using a smooth bore liner in the hoses ensures that they are easy to clean and maintain, prolonging their life span and saving you money in the long run.

High Purity Standards

For applications where hygiene and purity are critical, such as food and beverage, cosmetic, biopharma, and pharmaceutical industries, Aflex sanitary hose assemblies are the best option. These hoses are made under high-quality control standards, ensuring they meet the required sanitary specifications.

Excellent Performance in Extreme Temperatures

Aflex hoses can perform excellently in both high and low temperatures. They can withstand extreme temperatures ranging from -70°C to 260°C, making them versatile and suitable for various applications.

Wide Range of Applications

Aflex hoses are versatile and can be used in various applications, including chemical processing, food and beverage, pharmaceutical, cosmetic, biotech, and many more. This means you can use the hoses in different industries, depending on your needs.

Reduced Maintenance Costs

Aflex hoses require minimal maintenance, and their long life span means you'll spend less on replacements. This attribute makes them ideal for industries that seek to minimize operational costs.

Compliance with Industry Standards

Aflex hoses meet industry standards, including FDA, USP, and EN16643. This means that they are tested and certified safe for use in specific industries, ensuring that you use the right product for your applications.

Customizable Options

Aflex hoses have several customizable options, including various end fittings, bore sizes, and hose lengths. This allows you to tailor the hoses to your specific application needs.

Technical Support and Service

Liquidyne Process Technologies offers excellent technical support and service to its clients. Whether you need help selecting the proper hose or troubleshooting any issues, the company's customer service team is always available.

In conclusion, Aflex hoses are the perfect solution for industries requiring high chemical resistance, flexibility, and longevity hoses. Their excellent performance in extreme temperatures, a wide range of applications, and compliance with industry standards make them a top choice for process engineers, MRO managers, buyers, and scientists. Adopting Aflex hoses in your applications saves you money on maintenance and improves your applications' efficiency and effectiveness. Contact Liquidyne Process Technologies, Inc, today to learn how these our custom fabricated hoses benefit your processes.

Explore Liquidyne

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device