Understanding the Mechanics of Quattroflow Diaphragm Pumps: A Comprehensive Guide

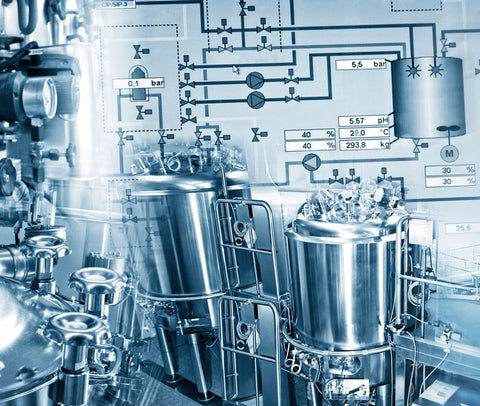

In process engineering, particularly within the sensitive and exacting fields of biopharmaceutical manufacturing, the selection of pumping technology is not merely a matter of efficiency—it's a critical component of process integrity and product quality. Among the myriad options available, Quattroflow diaphragm pumps stand out for their unique design and operational benefits. This comprehensive guide delves into the mechanics of Quattroflow diaphragm pumps, highlighting their four-piston diaphragm technology, the advantages this design offers, and how it compares to traditional pump technologies.

Introduction to Diaphragm Pumps

At the heart of diaphragm pump technology is a simple yet effective principle: using a flexible diaphragm to create a variable-volume chamber within the pump. As the diaphragm moves back and forth, it fills the chamber with the fluid to be pumped and then expels it, creating a flow. What sets Quattroflow diaphragm pumps apart is their unique method of achieving this action, specifically tailored to meet the rigorous demands of processes where product integrity is paramount.

The Quattroflow Four-Piston Diaphragm Technology

Quattroflow's distinctive feature is its four-piston diaphragm technology, which operates somewhat analogously to the engine in a car. However, instead of pistons driving a crankshaft, in Quattroflow pumps, the movement of the pistons directly drives the diaphragm. This design allows for a smoother, more balanced operation, reducing pulsation and shear forces on the pumped fluid—critical factors in applications involving delicate biologics or precise formulations.

How It Works

The Quattroflow pump consists of four diaphragms mounted on a centrally located shaft, each connected to its piston. These pistons are sequentially actuated by an eccentric shaft driven by an external motor, causing the diaphragms to move back and forth in a coordinated manner. This movement creates a gentle pumping action exceptionally suited for handling sensitive materials. The four diaphragms work in concert to ensure a continuous and smooth flow, minimizing the risk of damage to the product being pumped.

Advantages of Quattroflow Diaphragm Pumps

The Quattroflow design offers several key advantages, particularly in comparison to traditional pump technologies such as centrifugal or peristaltic pumps.

Gentle Handling of Sensitive Materials

The primary benefit of Quattroflow pumps is their ability to handle sensitive materials gently. The four-piston diaphragm technology ensures a low-shear, low-pulsation flow, which is crucial for maintaining the integrity of biological products, such as live cells or proteins, which can be damaged by excessive force or turbulence.

Accuracy and Precision

These pumps are highly accurate, offering precise control over flow rates. This precision is essential in processes requiring exact dosing or where the consistency of the product is paramount.

Dry Running and Self-Priming Capabilities

Quattroflow pumps can run dry without damage, a significant advantage in applications where priming fluid might not always be present. Additionally, their self-priming capability ensures quick and efficient startup and operation, even under challenging conditions.

Ease of Maintenance and Sterility

Designed with simplicity and cleanliness, Quattroflow pumps are easy to assemble and disassemble, facilitating maintenance and cleaning. For applications demanding sterility, such as pharmaceutical manufacturing, the pump's design minimizes contamination risks, and single-use models offer ultimate process security and convenience.

Comparison to Traditional Pump Technologies

While traditional technologies like centrifugal and peristaltic pumps have their place in many industrial applications, they can introduce challenges when used with sensitive or high-value products.

- Centrifugal pumps, for instance, can cause significant shear stress and product damage due to their high-speed rotational action.

- Peristaltic pumps, though gentler, still impart pulsation and can suffer from tubing wear, potentially compromising product integrity over time.

Quattroflow pumps, by contrast, offer a solution that combines the gentle handling required for sensitive materials with the operational efficiency, reliability, and cleanliness that process engineers need.

Conclusion

For process engineers in the biopharmaceutical industry and other fields where the integrity of the product is non-negotiable, understanding and leveraging the unique benefits of Quattroflow diaphragm pumps can be a game-changer. The four-piston diaphragm technology ensures gentle handling of sensitive materials and offers precision, reliability, and ease of maintenance critical for high-quality, efficient production processes.

Choosing the right pumping technology is paramount in a landscape where the cost of failure can be high, both in terms of product quality and financial implications. Quattroflow diaphragm pumps represent a sophisticated solution designed to meet the most demanding requirements, ensuring that process engineers have the tools they need to succeed in their mission-critical applications.